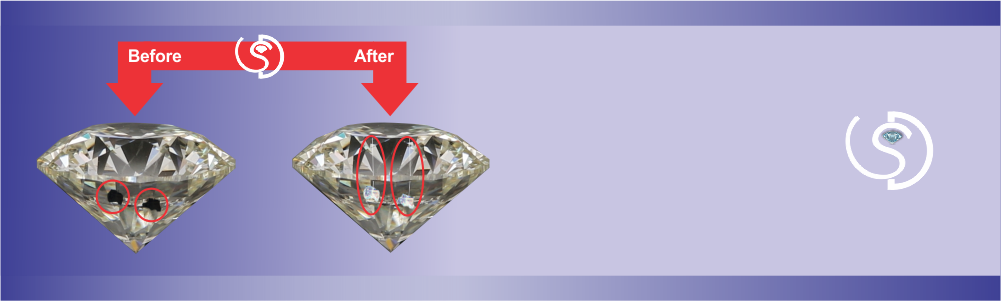

Laser drilling techniques have ability to selectively target, remove and significantly reduce the visibility of black carbon inclusions on a microscopic scale.

The laser drilling process involves the use of an infrared laser to bore very fine holes into a diamond to create a route of access to a black carbon crystal inclusion..

The laser then burns a narrow tube or channel to the inclusion. Once the location of included black carbon crystal has been reached by the drill channel, to dissolve the black carbon crystal.

After this process the black carbon crystal will dissolve and become transparent and sometimes slightly whitish opaque.

Under microscopic inspection the fine drill or bore holes can be seen, but are not distracting and do not affect sparkle or brilliance of the diamond.

While the channels are usually straight in direction, from an entry point on the surface, some drilling techniques are drilled from within, using naturally occurring fractures inside the stone to reach the inclusion in a way that mimics organic "feathers"

The channels are microscopic so that dirt or debris cannot travel down the channel. The surface-reaching holes can only be seen by reflecting light off of the surface of the diamond during microscopic viewing such as a jeweler's 10x magnifying lens or loupe and are invisible to the naked eye.

This process also improves the Diamond quality and Valuation.